HERZOG Open House 2025:

Innovations, investments and

international get-together in Oldenburg

![]()

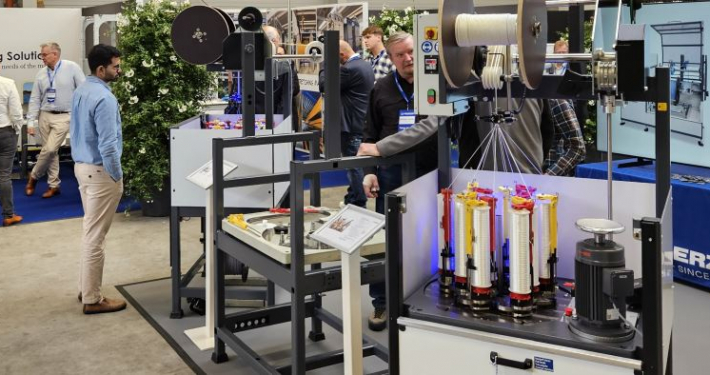

Every four years, HERZOG GmbH hosts its traditional in-house exhibition at its company premises in Oldenburg-Ofenerdiek. Already for the 9th time, customers and interested companies, universities and friends of the company, were able to find out about the latest developments in braiding and winding technology and experience state-of-the-art engineering from October 6 to 10, 2025.

More than 300 visitors (140 companies) from 35 countries made their way to Lower Saxony and took advantage of the opportunity to take a tour through the entire plant – it was possible to explore the brand new, high-precision metal processing centres in production, the in-house plastic injection moulding facility, and the training and testing centre. Work at the company continued unabated during this exciting week, allowing guests to watch live as components and parts were assembled into high-performance machines and HERZOG carriers were mounted with careful craftsmanship and attention to detail.

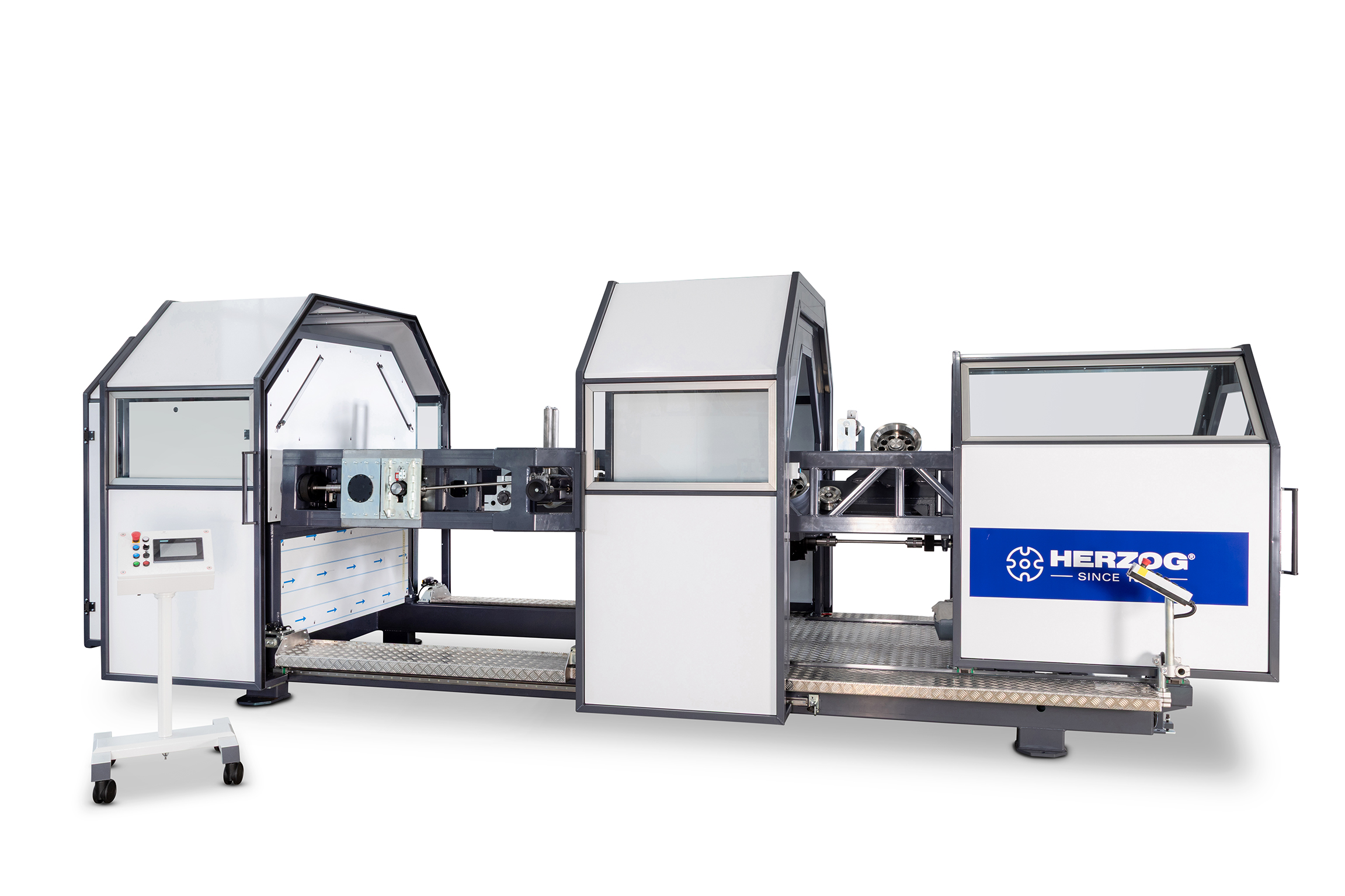

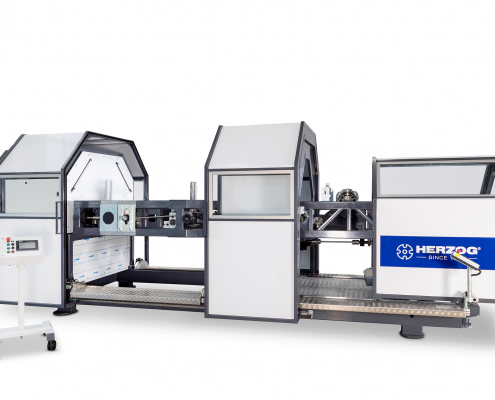

HERZOG presented more than 60 braiding and winding machines, pay-off and take-up systems, creels and stranding machines in seven exhibition areas spread across the entire factory premises. This enabled to show a wide range of the production portfolio, which comprises over 900 machine types. This selection of machines was intended to address as many industries and applications for braiding technology as possible: Fishing and seafaring, sports and leisure, the textile industry and the offshore sector. Also on display were braiding machines that can be used to manufacture products for medical or technical applications. In addition, cable harness braiding machines were used to demonstrate how cable harnesses, such as those used in aerospace or agricultural vehicles, can be braided with a protective covering.

More than 40 new and further developments

Another aspect of the mechanical engineering company’s product strategy is that, depending on customer requirements, both standard machines and customised special solutions can be designed and manufactured. In close consultation and cooperation with long-standing customers, machines are continuously improved, enhanced or redesigned. Over 40 new developments were presented at the in-house exhibition and explained in detail to guests.

The focus was on concepts such as automation, machine control, process reliability, user-friendliness and work ergonomics, as well as increasing production speed and reducing maintenance costs for certain types of machines.

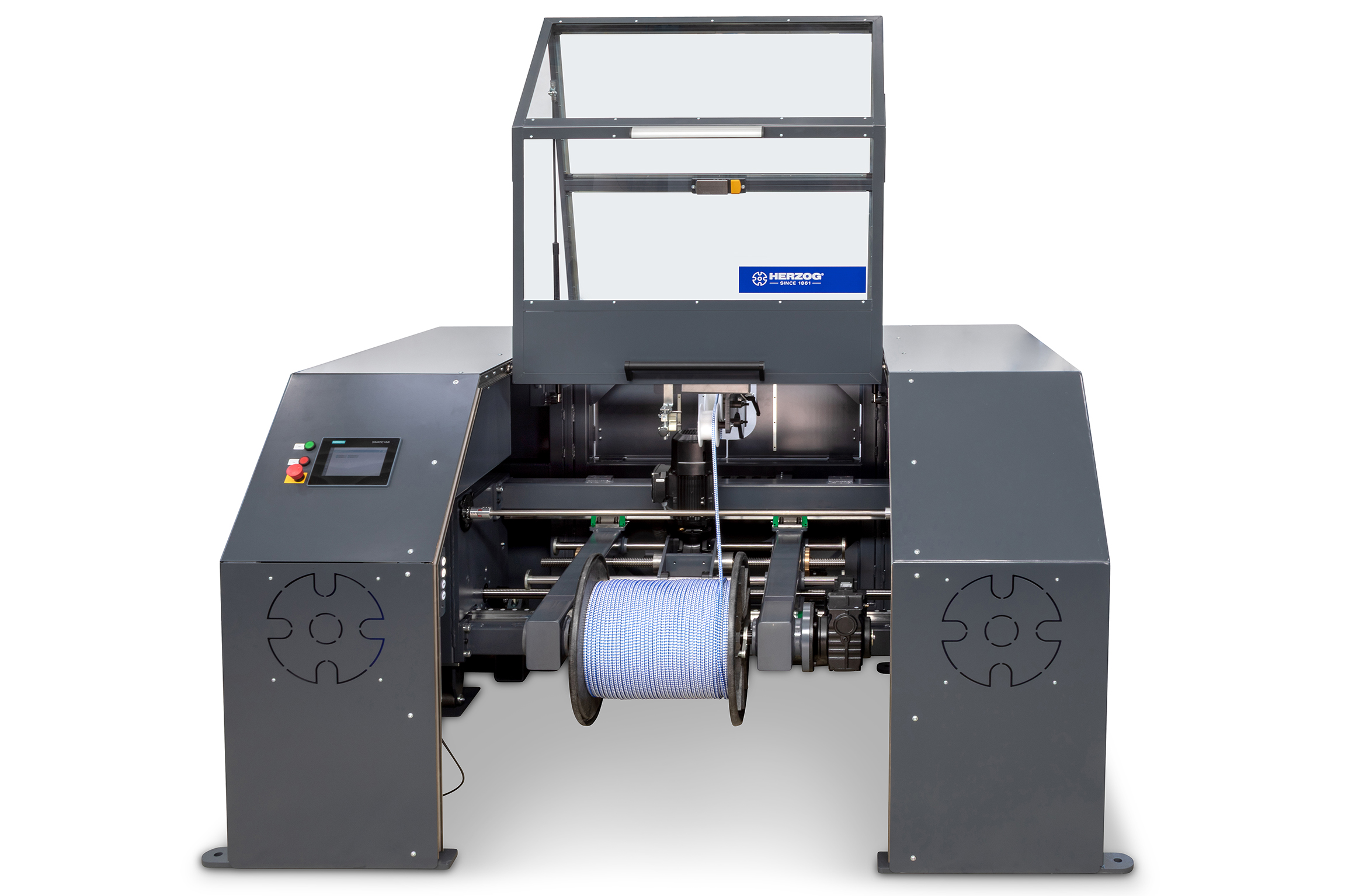

One key feature of this year’s show was the further development of machines in the 140 mm pitch size. The braiding body of these machines has been redesigned and now features a split top plate, which significantly reduces the effort required for mechanical maintenance and clearly increases machine availability. By adjusting the position of the control cabinet and the braid take-up, both the space requirement is reduced and the working ergonomics for the machine operator is improved. Furthermore, the production speed of this machine type could be increased by adapting specific components – up to 15–28%, depending on the material being processed.

Speed increases are now also possible for machines with a pitch size of 80 mm: depending on the material, up to 500 horn gear revolutions per minute can be reached and the output increased accordingly.

As of now, sleeve braiding machines with a 140 mm pitch size are also available. As a result, the bobbin capacity is increased by 100% – this makes every second bobbin change obsolete and reduces production costs enormously!

A wide range of innovations and innovations were also presented in the field of rope braiding machines: an advanced auxiliary take-off and a new type of hard metal coating enable improved rope guidance and higher pulling forces in the take-off system. Additionally, the ‘slippage’ of the braid is reduced. A new cost-efficient braiding die with electronic monitoring, a meter counting unit for more precise length measurement, and pay-off and take-up units on the machine underframe will further optimise rope manufacturing capabilities in the future.

The long-proven harness braiding machines will in future be equipped with exchangeable horn gear inserts and improved sound insulation – significantly enhancing the machine operator’s working environment. The KBB series is now complemented by an Eco version with a product slide instead of a take-off disc – a cost-optimised solution for shorter harnesses.

In the field of medical braids – recently a very dynamic market – significant progress has also been made in process reliability through refinements to machine control systems. With the help of PLC-controlled carrier exchange, work processes such as colour, material or pattern changes can be carried out automatically – without any manual intervention by an operator. On the one hand, this increases the reproducibility of the process, while on the other hand, set-up times and thus labour costs are significantly reduced.

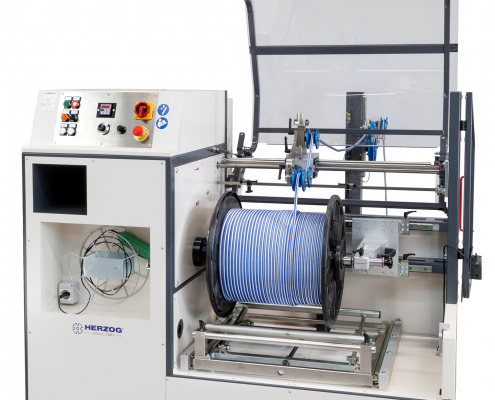

HERZOG understands ‘braiding’ as a holistic process with the winding process as a fundamentally important preliminary step. Only an optimally wound bobbin guarantees a perfect braiding result. For this reason, HERZOG winding machines are also undergoing continuous development and are now operated with the electronic traverse system ‘Servo’ – for even more perfect and faultless winding of the material onto the bobbin.

Completely new machines were introduced, such as the semi-automatic rewinding machine USP 450 Eco for use of larger drums and the take-up AWST 630 with traversing drum for gentle winding of sensitive products such as hoses, cables or wire. A new belt conveyor has also been developed for processing these sensitive products: the BA 500-130 can convey products up to 130 mm in diameter with a pulling force of 5,000 N, while regulating the contact pressure precisely to match the application.

The event was supplemented by 11 partner exhibitors, who were able to present their products that complement the braiding process, establish contacts, and develop exciting ideas.

Investments at the Oldenburg site

HERZOG also presented its future plans for the company to visitors at the in-house exhibition: the company has made a conscious decision to remain in Oldenburg and to further expand its production and assembly capacities at its current location. Over the past two years, seven new metal processing machines, with a total value of over three million euros, have been put into operation – a significant increase in production capacity and capabilities through modernisation and automation. With around 70% of parts manufactured in-house, customers can be supplied with the parts they need quickly and flexibly. Construction of a new sales building has recently begun, which will create around 220 square metres of new assembly space in the production hall.

‘With these investments, we are strengthening the production depth and flexibility of our site and laying the foundation for further growth,’ emphasise managing directors Swantje Horn and Dennis Behnken. Further measures for modernisation and expansion are already in the planning stage.

International resonance and HERZOG culture in action

The Open House 2025 was organised entirely by the HERZOG team – from setting up the exhibition areas, booths and machines to providing a shuttle service for our guests, catering and supporting visitors. Visitors praised the open atmosphere, the high level of expertise and the exceptional friendliness of the entire team.

At the end of each day of the trade fair, many participants gathered for a convivial get-together and had the opportunity to engage in interesting talks with the HERZOG team and agents from 25 countries. On the final Friday, HERZOG opened its doors for a ‘Family & Friends’ day, during which employees, relatives and partner companies were able to experience the business up close – a successful end to an eventful week.

Tradition and future – made in Oldenburg

With its 2025 in-house exhibition, HERZOG impressively demonstrated that technological innovation and regional roots can be combined perfectly. As a fifth-generation family-run company, HERZOG focuses on long-term thinking, continuity and a strong team. See for yourself in the new company film, which premiered at the show.

With more than 150 employees and over 12,000 m² of state-of-the-art production space, the company has been supplying customers all over the world with technology ‘Made in Germany’ since 1861.